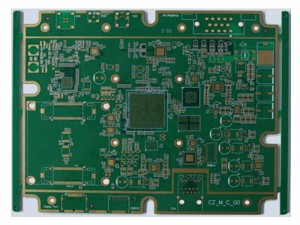

A PCB tarogwajin tsayawa na'urar da ake amfani da ita don gwada samfuran ƙarshen taron PCB.A lokacin da yin PCB taro gwajin racks, PCB taro sarrafa shuke-shuke yawanci bukatar samar da Gerber fayiloli da PCB taro samfurori don sauƙaƙe samar da gwajin racks.Don benci na gwaji na taron PCB na yanzu, ƴan buckles farantin matsa lamba ne kawai aka shigar akan dandamalin gwaji, kuma taron PCB yana daidaitawa ta thimble da matsin farantin karfe.Yayin gwajin aikin taron PCB, danna taron PCB cikin matse da hannaye biyu.Saboda PCB taro tare da m ƙarfi ko rashin isashen latsawa, yana da sauƙi don sanya fil ɗin gwajin kuma taron PCB yana da mummunan hulɗa, wanda ke tasiri sosai ga ingancin gwajin da daidaito.Idan ƙarfin ya yi girma da yawa, yana da sauƙi don lalacewa ko lalacewa lokacin da aka danna taron PCB, kuma yana da sauƙi don lalata fil ɗin gwajin.haifar da babban hasara.

1. Shirye-shiryen kayan aiki.

Bayan kayyade shirin bisa ga bayanai, shi wajibi ne don shirya hardware kayan (electronic sassa), alaka da na gefe da'irori, kayan aiki, firam kayan (kamar acrylic allon), manne, lantarki batch, sukurori, waya kayan, da dai sauransu. don ƙayyade bayanai don tsarin samarwa.

2. Ƙaddara da dubawa na tsarin gwajin gwajin

3. Abubuwan buƙatun waya

(1) Buɗewar waya yana buƙatar buɗewa a cikin 2mm.Da farko ƙara tin zuwa buɗaɗɗen waya da matsayin tin waya na allurar gwaji.

(2) Wayar da aka yi masa walda kada ta kasance tana lilo ko sassautawa.

(3) Ware wayoyi masu ƙarfi da rauni a cikin gwajin gwajin kuma ɗaure wayoyi tare da wayoyi.

(4) Dole ne a shigar da mahaɗin ammeter da voltmeter tare da alƙalami mai yawa.Ba za a iya shigar da matosai na ayaba don gwada halin yanzu, ƙarfin lantarki da sauran ayyuka don tabbatar da amincin mai aiki ba.

(5) Layin siginar haɗin haɗin samfurin samfuri mai girma dole ne ya yi amfani da waya mai kariya don tabbatar da amincin ƙasa na cibiyar sadarwar waje.

(6) Idan akwai wuta a ma'aunin ma'auni, dole ne a daskare kwanon wutar.

(7) Dole ne a shigar da ma'aunin gwajin fuse, kuma ba za a iya maye gurbinsa da wayoyi ko wasu wayoyi masu gudanarwa ba.Cire fis ɗin 13A akan filogi na asali.Lokacin maye gurbin fuse, kula da nawa samfurin a ƙarƙashin bukatun gwaji.An ƙayyade ka'idar maye gurbin ta hanyar aiki na yanzu na samfurin sau 8 -10 ya isa.

4. Zaɓin maki don dubawa mai inganci dole ne ya bi ka'idodin cikakke, tasiri da tattalin arziki.

PCBFuture ya gina mu mai kyau suna a cikin cikakken turnkey PCB taro sabis masana'antu dominsamfur PCB taroda ƙananan girma, tsakiyar girma PCB taro.Abin da abokan cinikinmu ke buƙatar yi shi ne aika fayilolin ƙirar PCB da buƙatun zuwa gare mu, kuma za mu iya kula da sauran ayyukan.Muna da cikakkiyar ikon bayar da sabis na PCB na turnkey wanda ba za a iya doke su ba amma kiyaye jimlar farashi a cikin kasafin ku.

Idan kuna neman ƙwararrun masana'anta PCB na Turnkey, da fatan za a aika fayilolin BOM ɗinku da fayilolin PCB zuwasales@pcbfuture.com.Duk fayilolinku sirri ne sosai.Za mu aiko muku da ingantaccen zance tare da lokacin jagora cikin sa'o'i 48.

Lokacin aikawa: Agusta-23-2022