Domin inganta samar da inganci da kuma rage farashin samarwa aPCB tarotsari, danda kewaye allon yawanci yi a panel don samarwa, wanda zai iya sauƙaƙe PCBA sarrafa shuka don gudanar da guntu waldi.Masu zuwa za su yi magana game da hanyoyin gama gari da ka'idojin hukumar da'ira.

Ka'idodin PCB panelization:

1. Girman PCB panel panel nisa ≤ 300mm (Layin Fuji);idan ana buƙatar rarrabawa ta atomatik, girman PCB ya kamata ≤ 125mm(W) × 180mm(L).

2. The siffar PCB za su kasance kusa da square har zuwa yiwu, da kuma shawarar splicing jirgin ne (2*2,3 *3,4* 4) a kowane panel.

3. Firam ɗin waje (ƙwaƙwalwar ƙugiya) na allon kewayawa zai ɗauki ƙirar rufaffiyar madauki don tabbatar da cewa kwamitin PCB ba zai gurɓata ba bayan an daidaita shi a kan na'urar.

4. The kananan PCB hukumar nesa za a sarrafa a 75mm ~ 145mm.

5. Ba za a sami manyan na'urori ko na'urori masu tasowa kusa da ma'anar haɗin kai tsakanin firam ɗin waje na katako na katako da ƙananan katako na ciki ba, kuma za a sami sarari fiye da 0.5mm tsakanin sassan da gefen PCB kwamitin zuwa tabbatar da aikin yau da kullun na kayan aikin yankan.

6. A kusurwoyi huɗu na firam ɗin PCB na waje, an buɗe ramuka guda huɗu kuma diamita na rami shine (4mm ± 0.01mm);Ƙarfin rami ya zama matsakaici don tabbatar da cewa ba zai karye ba yayin aiwatar da kaya da saukewa;Diamita na rami da daidaiton matsayi zai zama babba, kuma ramin ya zama santsi.

7. Kowane ƙaramin allo a cikin PCB dole ne ya kasance yana da aƙalla ramuka guda uku, 3 ≤ rami diamita ≤ 6mm, kuma ba a yarda da wiring ko SMT a cikin 1mm na ramin sakawa gefen.

8. A lokacin da kafa tunani sakawa batu, wani mara juriya waldi yankin 1.5mm girma fiye da sakawa batu yawanci ajiye a kusa da sakawa batu.

9. Za a samar da manyan abubuwan haɗin gwiwa tare da ginshiƙai ko sanya ramuka, kamar: makirufo, ƙirar baturi, microswitch, ƙirar lasifikan kai, mota, da sauransu.

Hanyoyin haɗin PCB na gama gari a cikin panel:

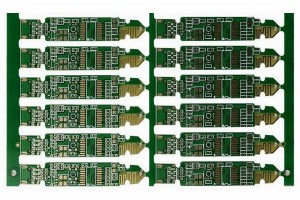

1, V-CUT

V-CUT yana nufin ana iya haɗa allo da yawa ko allo ɗaya a haɗa su tare, sannan za a iya yanke V-Groove tare da injin V-CUT tsakanin allunan bayan sarrafa PCB, wanda za'a iya karyewa yayin amfani.Hanya ce da ta fi shahara a zamanin yau.

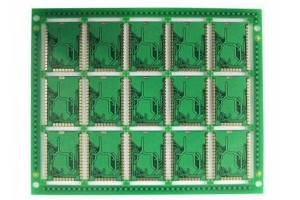

2. Tsagi mai naushi

Yin naushi na nufin niƙa fanko tsakanin faranti ko cikin faranti tare da injin niƙa kamar yadda ake buƙata, wanda yayi daidai da tonowa.

3. Ramin tambari

Wannan yana nufin amfani da ƙaramin rami don haɗa allon PCB, wanda yayi kama da siffar sawtooth akan tambarin, don haka ana kiran shi hanyar haɗin hatimi.Haɗin ramin hatimi yana buƙatar babban iko mai ƙarfi a kusa da allon, wato ɗan ƙaramin hatimi ne kawai za a iya amfani da shi don maye gurbin layin V.

Kana son ƙarin sani, da fatan za a danna: www.PCBfuture.com

Lokacin aikawa: Janairu-13-2022