nau'i 16naPCB gama garisolderinglahani

A cikin tsarin hada PCB, lahani iri-iri sau da yawa suna bayyana, kamar sayar da karya, zafi mai zafi, gada da sauransu.A ƙasa PCBfuture zai bayyana al'adaPCB tarolahani lokacin siyar da PCBs da yadda ake guje mata.

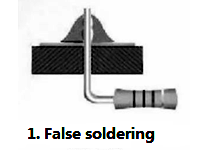

1. Qarya soldering

Siffofin bayyanar: akwai iyakoki na baƙar fata a bayyane tsakanin mai siyar da gubar, ko foil ɗin tagulla, kuma mai siyar yana manne da iyaka.

Cutarwa: rashin aiki da kyau.

Dalili: gubar na abubuwan da aka gyara ba a tsaftacewa ba, tin ba a sanya shi ba ko tin yana da oxidized.Ba a tsabtace allon da'irar da aka buga ba, kuma ingancin spraying ba shi da kyau.

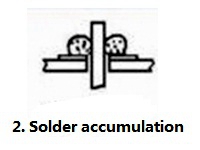

2. Tarin solder

Siffofin bayyanar: tsarin haɗin gwiwa na solder yana da sako-sako, fari da haske.

Cutarwa: rashin isasshen ƙarfin inji na iya haifar da walda ta ƙarya.

Dalili: rashin ingancin solder.Yanayin walda bai isa ba.Lokacin da mai siyar ba ta inganta ba, jagorar bangaren yana kwance.

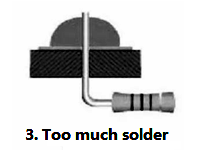

3. Yawan saida

Siffofin bayyanar: farfajiyar siyar tana da ma'ana.

Cutarwa: solder yana ɓarna kuma ƙila ba a iya ganin lahani cikin sauƙi.

Dalili: aikin da ba daidai ba a lokacin soldering.

4. Dan solder kadan

Siffofin bayyanar: yankin walda ba shi da ƙasa da 80% na kushin, kuma mai siyarwar ba ya samar da shimfidar wuri mai santsi.

Cutarwa: rashin isasshen ƙarfin inji.

Dalili: motsin solder mara kyau ko cirewar da ba a kai ba.Rashin isassun kwarara.Lokacin walda yayi gajere sosai.

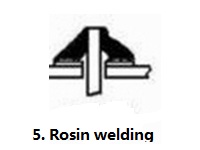

5. Rosin walda

Siffofin bayyanar: akwai rosin slag a cikin walda.

Cutarwa: rashin isasshen ƙarfi, rashin kulawa, wani lokacin kunna da kashewa.

Dalili: akwai injunan walda ko gazawar walda.Rashin isasshen lokacin walda da dumama.Ba a cire fim ɗin oxide na saman ba.

6. Yawan zafi

Siffofin bayyanar: haɗin haɗin gwiwa na solder, babu ƙarfe mai haske, m surface.

Cutarwa: kushin yana da sauƙin kwasfa kuma an rage ƙarfin.

Dalili: ƙarfin ƙarfe na ƙarfe yana da girma da yawa, kuma lokacin dumama ya yi tsayi da yawa.

7. Sanyin walda

Siffofin bayyanar: Filayen granular ne, kuma wani lokacin ana iya samun fasa.

Cutarwa: Ƙarfin ƙarfi da ƙarancin aiki.

Dalili: Ana girgiza mai saida kafin ya dage.

8. Rashin kutse

Siffofin bayyanar: mu'amala tsakanin solder da weldment ya yi girma da yawa kuma ba santsi ba.

Cutarwa: ƙarancin ƙarfi, babu damar shiga ko kunnawa da kashewa.

Dalili: ba a tsabtace walda ba.Flux bai isa ba ko rashin inganci.Weldment bai cika zafi ba.

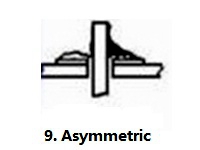

9. Asymmetric

Fasalolin bayyanar: solder baya gudana akan kushin.

Cutarwa: Rashin isasshen ƙarfi.

Dalili: solder yana da rashin ruwa mara kyau.Rashin isassun ruwa ko rashin inganci.Rashin isasshen dumama.

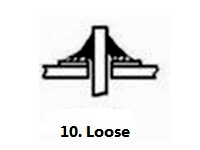

10. Sako

Halayen bayyanar: Ana iya motsa waya ko jagorar bangaren.

Cutarwa: mara kyau ko mara kyau.

Dalili: kafin mai saida ya yi ƙarfi, wayar gubar tana motsawa don haifar da ɓarna.Ba a sarrafa gubar da kyau.

11. Cuf

Halayen bayyanar: kaifi.

Cutarwa: mummunan bayyanar, mai sauƙin haifar da gada

Dalili: juzu'i kaɗan da tsayin lokacin dumama.Ƙaƙwalwar barin ƙarfen ƙarfe ba daidai ba ne.

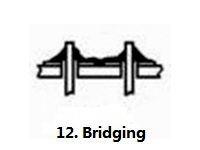

12. Gada

Halayen bayyanar: an haɗa wayoyi masu kusa.

Cutarwa: Gajeren kewayawa na lantarki.

Dalili: da yawa solder.Ba daidai ba kusurwa na ja da baya na soldering baƙin ƙarfe.

13. Fitowa

Fasalolin bayyanar: dubawa na gani ko ƙaramar ƙarfi na iya ganin ramuka.

Cutarwa: rashin isasshen ƙarfi, haɗin gwiwar solder mai sauƙin lalata.

Dalili: rata tsakanin gubar da ramin kushin ya yi girma da yawa.

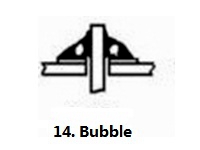

14. Kumfa

Siffofin bayyanar: akwai kumburin siyar da wuta mai hura wuta a tushen gubar, kuma wani rami yana ɓoye a ciki.

Cutarwa: Gudanarwar wucin gadi, amma yana da sauƙi don haifar da rashin daidaituwa na dogon lokaci.

Dalili: rata tsakanin gubar da rami na walda yana da girma.Rashin shigar gubar.Lokacin waldawa na toshe mai gefe biyu ta ramuka yana da tsayi, kuma iska a cikin ramukan yana faɗaɗa.

15. Tagulla baƙar fata

Siffofin bayyanar: an cire foil ɗin jan ƙarfe daga allon da aka buga.

Cutarwa: PCB ya lalace.

Dalili: lokacin walda ya yi tsayi da yawa kuma zafin jiki ya yi yawa.

16. A tuɓe

Halayen bayyanar: kayan haɗin gwal suna barewa daga bangon jan karfe (ba foil na jan karfe da PCB ba).

Cutarwa: Buɗe kewaye.

Dalili: mummunan rufin ƙarfe akan kushin.

PCBFuture yana ba da duk sabis na taro na PCB wanda ya haɗa da PCB masana'anta, samar da kayan masarufi da taron PCB.MuTurnkey PCB sabisyana kawar da buƙatar ku don sarrafa masu samar da kayayyaki da yawa a cikin firam ɗin lokaci da yawa, yana haifar da haɓaka aiki da ƙimar farashi.A matsayin kamfani mai inganci, muna ba da cikakkiyar amsa ga bukatun abokan ciniki, kuma muna iya ba da sabis na lokaci da keɓaɓɓen sabis waɗanda manyan kamfanoni ba za su iya yin koyi da su ba.Za mu iya taimaka muku guje wa lahanin saida PCB a cikin samfuran ku.

Lokacin aikawa: Nuwamba-06-2021