Me ya sa za mu toshe vias a cikin PCB?

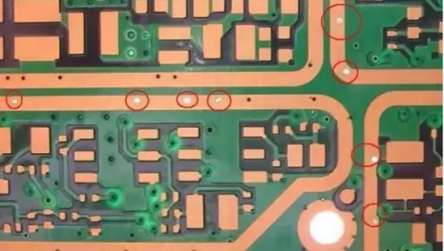

Domin biyan bukatun abokan ciniki, dole ne a toshe ta hanyar ramukan da'ira.Bayan aiki mai yawa, ana canza tsarin ramin filogi na al'ada na al'ada, kuma ana amfani da farar net ɗin don kammala waldawar juriya da toshe rami na farfajiyar da'ira, wanda zai iya sa samar da kwanciyar hankali da ingantaccen abin dogaro.

Via rami yana taka muhimmiyar rawa a cikin haɗin kai na da'irori.Tare da haɓaka masana'antar lantarki, yana haɓaka haɓakar PCB, kuma yana gabatar da buƙatu mafi girma donPCB ƙirƙira da tarofasaha.Ta hanyar fasahar toshe rami ta samo asali, kuma ya kamata a cika waɗannan buƙatu:

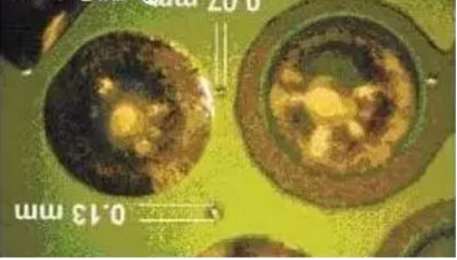

(1) Tagulla a cikin ta rami ya isa, kuma ana iya toshe abin rufe fuska ko a'a;

(2) Dole ne a sami tin da gubar a cikin ramin, tare da ƙayyadaddun buƙatu mai kauri (4 microns), babu mai siyar da tawada mai hana tawada a cikin ramin, yana haifar da ɓoyayyiyar kwano a cikin ramukan;

(3) Dole ne a sami rami mai juriya tawada tawada a cikin ta ramin, wanda ba a fili yake ba, kuma dole ne babu zoben gwangwani, gwangwani da lebur.

Tare da haɓaka samfuran lantarki a cikin hanyar "haske, bakin ciki, gajere da ƙanana", PCB kuma yana haɓaka zuwa babban yawa da wahala.Saboda haka, babban adadin SMT da BGA PCBs sun bayyana, kuma abokan ciniki suna buƙatar toshe ramuka lokacin hawa abubuwan haɗin gwiwa, waɗanda galibi suna da ayyuka biyar:

Tare da haɓaka samfuran lantarki a cikin hanyar "haske, bakin ciki, gajere da ƙanana", PCB kuma yana haɓaka zuwa babban yawa da wahala.Saboda haka, babban adadin SMT da BGA PCBs sun bayyana, kuma abokan ciniki suna buƙatar toshe ramuka lokacin hawa abubuwan haɗin gwiwa, waɗanda galibi suna da ayyuka biyar:

(1) Domin hana gajeriyar da'ira lalacewa ta hanyar da tin shiga ta cikin kashi surface a lokacin PCB a kan igiyar ruwa soldering, musamman a lokacin da muka sanya ta hanyar rami a kan BGA kushin, dole ne mu fara yin toshe rami sa'an nan zinariya plating don sauƙaƙe BGA soldering. .

(2) Guji ragowar ruwa a cikin ramuka;

(3) Bayan da surface Dutsen da bangaren taro na Electronics factory, da PCB kamata sha injin don samar da mummunan matsa lamba a kan gwajin inji;

(4) Hana siyar da saman ƙasa ta kwarara cikin rami, da haifar da siyarwar ƙarya da kuma shafar dutsen;

(5) hana ƙwanƙolin solder daga fitowa a lokacin sayar da igiyar ruwa, da haifar da gajeren kewayawa.

Gane fasahar toshe rami don ta rami

DominSMT PCB taroallon, musamman hawan BGA da IC, toshe ta hanyar rami dole ne ya zama lebur, madaidaicin da concave da ko ragi 1mil, kuma dole ne babu jan tin a gefen ramin;domin saduwa da abokin ciniki ta bukatun, da ta hanyar rami toshe rami tsari za a iya bayyana a matsayin multifarious, dogon tsari kwarara, wuya tsari iko, akwai sau da yawa matsaloli kamar man drop a lokacin zafi iska matakin da kore mai solder juriya gwajin da kuma mai fashewa bayan. waraka.Dangane da ainihin yanayin samarwa, muna taƙaita matakai daban-daban na toshe rami na PCB, kuma muna yin kwatancen da haɓakawa a cikin tsari da fa'idodi da rashin amfani:

Lura: ka'idar aikin daidaitawar iska mai zafi shine don amfani da iska mai zafi don cire abin da ya wuce kima a saman allon da'irar da aka buga da kuma a cikin rami, kuma sauran solder an rufe shi daidai a kan kushin, layin da ba tare da toshewa ba da wuraren marufi. , wanda yana daya daga cikin hanyoyin da ake amfani da su wajen maganin da'ira da aka buga.

1. Toshe rami tsari bayan zafi iska matakin: farantin surface juriya waldi → HAL → toshe rami → curing.Ana ɗaukar tsarin rashin toshewa don samarwa.Bayan daidaitawar iska mai zafi, ana amfani da allon aluminum ko allon toshe tawada don kammala filogin rami na duk garukan da abokan ciniki ke buƙata.Toshe rami tawada na iya zama tawada mai ɗaukar hoto ko tawada mai zafi, a yanayin tabbatar da launi ɗaya na rigar fim ɗin, tawada mai toshe rami ya fi kyau a yi amfani da tawada iri ɗaya da allon.Wannan tsari zai iya tabbatar da cewa ta rami ba zai sauke mai bayan zafi iska matakin, amma yana da sauki sa toshe rami tawada ya gurbata farantin surface da kuma m.Yana da sauƙi ga abokan ciniki su haifar da siyarwar ƙarya yayin hawa (musamman BGA).Don haka, abokan ciniki da yawa ba sa karɓar wannan hanyar.

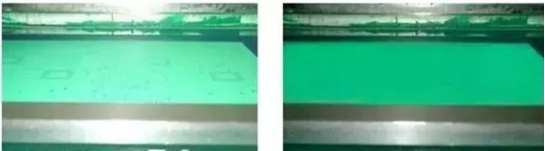

2. Toshe rami tsari kafin zafi matakin matakin: 2.1 toshe rami tare da aluminum takardar, m, niƙa farantin, sa'an nan canja wurin graphics.Wannan tsari yana amfani da injin hakowa na CNC don fitar da takardar aluminum wanda ke buƙatar toshe rami, yin farantin allo, ramin toshe, tabbatar da cikakken ramin ramin rami, toshe rami tawada, tawada na thermosetting kuma ana iya amfani dashi.Dole ne halayensa su zama babban taurin, ƙananan canjin raguwa na guduro, da mannewa mai kyau tare da bangon rami.Tsarin fasaha shine kamar haka: pretreatment → ramin toshe → farantin niƙa → canja wurin tsari → etching → walƙiya juriya na farantin.Wannan hanya na iya tabbatar da cewa ramin toshe ramin yana da santsi, kuma daidaitawar iska mai zafi ba zai sami matsala masu inganci kamar fashewar mai da faɗuwar mai a gefen ramin ba.Koyaya, wannan tsari yana buƙatar kauri na jan karfe na lokaci ɗaya don sanya kaurin tagulla na bangon rami ya dace da ma'aunin abokin ciniki.Sabili da haka, yana da manyan buƙatu don saka tagulla na duka farantin karfe da aikin injin niƙa, don tabbatar da cewa an cire resin a saman jan ƙarfe gaba ɗaya, kuma saman jan ƙarfe yana da tsabta kuma ba gurɓatacce ba.Yawancin masana'antun PCB ba su da tsari mai kauri na lokaci ɗaya, kuma aikin kayan aikin ba zai iya biyan buƙatun ba, don haka ba a cika yin amfani da wannan tsari a masana'antar PCB ba.

(The blank silk screen) (The stall point film net)

We are helpful, attentive and supportive with a proactive approach to help you win in competitive markets. For more information, please email to service@pcbfuture.com.

Lokacin aikawa: Jul-01-2021