A cikin PCB proofing, an riga an sanya wani Layer na resist tin a kan ɓangaren tagulla don kiyaye shi a saman Layer na allo, wato, ɓangaren da'irar, sannan sauran foil ɗin tagulla an haɗa su da sinadarai. nesa, wanda ake kira etching.

Don haka, inPCB tabbaci, Wadanne matsaloli ya kamata a kula da su a cikin etching?

Ingancin abin da ake buƙata na etching shine a sami damar cire dukkan yadudduka na tagulla gaba ɗaya sai a ƙarƙashin Layer na anti-etching.Magana mai mahimmanci, ingancin etching dole ne ya haɗa da daidaitattun faɗin waya da matakin etching gefe.

Matsalar etching ta gefe tana yawan tasowa kuma ana tattaunawa a cikin etching.Matsakaicin nisa na gefen etch zuwa zurfin etch ana kiransa da etch factor.A cikin masana'antar da'ira da aka buga, ƙaramin digiri na gefe ko ƙaramin ƙima shine mafi gamsarwa.Tsarin kayan aikin etching da nau'o'in nau'i daban-daban na maganin etching zai shafi ma'aunin etching ko digiri na gefe.

Ta hanyoyi da yawa, ingancin etching yana wanzuwa tun kafin allon kewayawa ya shiga injin etching.Saboda akwai kusancin ciki na kusa tsakanin matakai daban-daban na tabbatar da PCB, babu wani tsari wanda wasu hanyoyin ba su shafa ba kuma baya shafar wasu matakai.Yawancin matsalolin da aka gano a matsayin ingancin etch sun wanzu a cikin tsarin cirewa tun da farko.

Maganar ka'ida, tabbatar da PCB yana shiga matakin etching.A cikin tsarin tsarin lantarki, yanayin da ya dace ya kamata ya kasance: jimlar kauri na jan karfe da tin gubar bayan electroplating kada ya wuce kauri na fim din na'urar daukar hoto, ta yadda tsarin electroplating ya rufe gaba daya a bangarorin biyu na fim din."bangon" yana toshewa kuma an saka shi a ciki.Duk da haka, a cikin ainihin samarwa, tsarin sutura ya fi girma fiye da yanayin hotuna;tun da tsayin rufin ya zarce fim ɗin mai ɗaukar hoto, akwai yanayin tarawa na gefe, kuma tin ko tin-tin tsayayya Layer da aka rufe sama da layin ya shimfiɗa zuwa bangarorin biyu, yana samar da "Edge", ƙaramin sashi na fim ɗin hotuna. an rufe shi a ƙarƙashin "baki"."Gidan" da aka kafa ta tin ko gubar-tin ya sa ba zai yiwu a cire fim din ba gaba daya lokacin cire fim din, barin wani karamin sashi na "sauran manne" a karkashin "gefen", wanda ya haifar da rashin cikawa.Layukan suna samar da "tushen jan karfe" a bangarorin biyu bayan etching, wanda ke rage tazarar layin, yana haifar dabuga allodon kasa cika buƙatun abokin ciniki kuma ana iya ƙi.Farashin samarwa na PCB yana ƙaruwa sosai saboda ƙin yarda.

A cikin tabbatarwa na PCB, da zarar an sami matsala tare da tsarin etching, dole ne ya zama matsalar batch, wanda a ƙarshe zai haifar da babban ɓoyayyiyar haɗari ga ingancin samfurin.Saboda haka, yana da mahimmanci musamman don nemo wanda ya dacePCB proofing manufacturer.

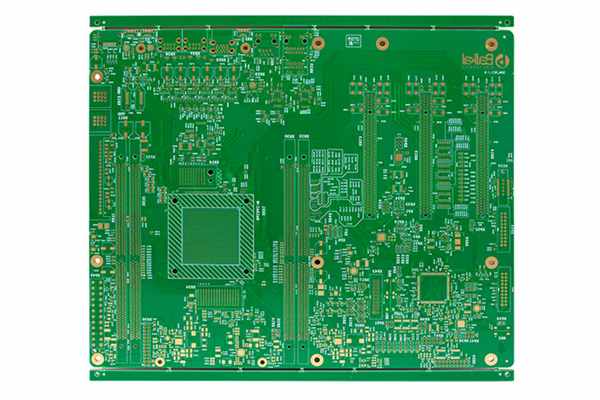

PCBFuture ya gina mu mai kyau suna a cikin cikakken turnkey PCB taro sabis masana'antu don samfur PCB taro da low girma, tsakiyar girma PCB taro.Abin da abokan cinikinmu ke buƙatar yi shi ne aika fayilolin ƙirar PCB da buƙatun zuwa gare mu, kuma za mu iya kula da sauran ayyukan.Muna da cikakkiyar ikon bayar da sabis na PCB na turnkey wanda ba za a iya doke su ba amma kiyaye jimlar farashi a cikin kasafin ku.

Idan kuna neman ƙwararrun masana'anta PCB na Turnkey, da fatan za a aika fayilolin BOM ɗinku da fayilolin PCB zuwasales@pcbfuture.com. Duk fayilolinku sirri ne sosai.Za mu aiko muku da ingantaccen zance tare da lokacin jagora cikin sa'o'i 48.

Lokacin aikawa: Dec-09-2022