1. Sanya Yatsa

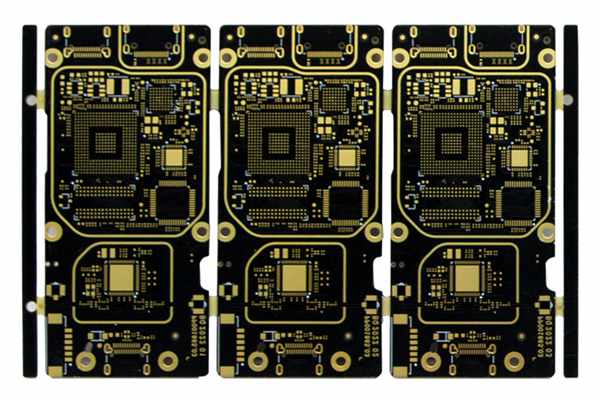

In PCB tabbaci, Ƙarfe da ba kasafai ake yi ba a kan mahaɗin gefen allo, gefen allon da ke fitowa lamba ko yatsan zinare don samar da ƙarancin juriya da juriya mai ƙarfi, wanda ake kira plating ɗin yatsa ko kuma fitowa fili.Tsarin shine kamar haka:

1) Bare murfin kuma cire murfin dalma ko gwangwani a kan abin da ke fitowa.

2) kurkure da ruwa.

3) gogewa da abrasive.

4) kunnawa yaduwa a cikin 10% sulfuric acid.

5) nickel plating kauri a kan protruding lamba ne 4-5 μm.

6) Tsaftace don cire ruwan ma'adinai.

7) zubar da maganin jiƙa na zinariya.

8) platin zinare.

9) tsaftacewa.

10) bushewa.

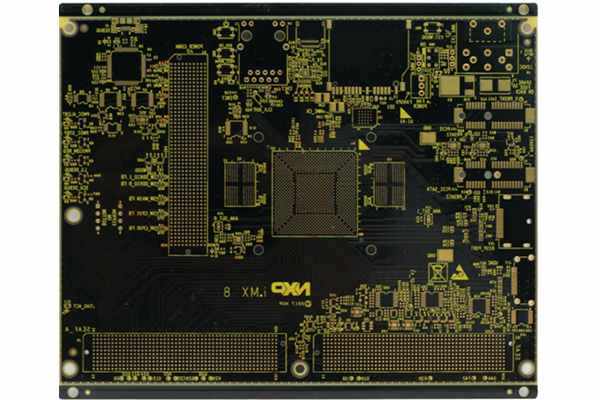

2. Ta hanyar plating

Akwai hanyoyi da yawa don saita ƙwararren electroplating Layer akan bangon rami na hakowa, wanda ake kira ramin bangon kunnawa a aikace-aikacen masana'antu.Tsarin amfani da kasuwanci na da'irar da aka buga yana buƙatar tankunan ajiya masu yawa, kowannensu yana da nasa kulawa da buƙatun kulawa.Via electroplating shi ne m zama dole masana'antu tsarin na hakowa masana'antu tsari.Lokacin da bututun ya yi rawar jiki ta cikin foil ɗin tagulla da abin da ke ƙarƙashinsa, zafin da ke haifarwa yana ɗaukar resin ɗin roba wanda ya ƙunshi mafi yawan abubuwan da ake amfani da su, kuma tarkacen guduro da sauran tarkacen hakowa sun taru a kusa da ramin kuma an lulluɓe su a kan sabon bangon ramin da aka fallasa. a cikin jakar tagulla, kuma resin da aka ƙulla zai bar wani Layer na zafi mai zafi akan bangon rami na substrate;Yana nuna ƙarancin mannewa ga yawancin masu kunnawa, wanda ke buƙatar haɓaka nau'in fasaha mai kama da aikin sinadari na cire tabo da lalata baya.

Hanyar da ta fi dacewa don tabbatar da PCB ita ce yin amfani da tawada mai ƙarancin danko na musamman, wanda ke da mannewa mai ƙarfi kuma ana iya haɗa shi cikin sauƙi zuwa ga mafi yawan bangon ramin goge mai zafi, don haka kawar da matakin koma baya.

3.Roller nasaba zaɓaɓɓen plating

Fil da fitilun tuntuɓar na'urorin lantarki, kamar haɗe-haɗe, haɗaɗɗun da'irori, transistor da madaukai masu sassauƙa, ana zaɓin farantin su don cimma kyakkyawar juriyar lamba da juriyar lalata.Wannan hanyar lantarki na iya zama da hannu ko ta atomatik.Yana da tsada sosai don dakatar da zaɓen plating na kowane fil daban-daban, don haka dole ne a yi amfani da batch waldi.A zabar hanyar plating, da farko sanya wani Layer na fim mai hanawa a kan sassan karfen tagulla waɗanda ba sa buƙatar electroplating, kuma kawai dakatar da lantarki akan foil ɗin jan ƙarfe da aka zaɓa.

4.Goge plating

Plating Brush fasaha ce ta electrostacking, wacce kawai ke dakatar da wutar lantarki a cikin iyakataccen yanki kuma ba ta da tasiri akan wasu sassa.Yawancin lokaci, karafa da ba kasafai ake yi ba akan zaɓaɓɓun sassa na allon da'irar da aka buga, kamar wurare kamar masu haɗa gefen allo.An fi amfani da goge goge a cikilantarki taro taron bitadon gyara allunan kewaye sharar gida.

PCBFuture ya gina mu mai kyau suna a cikin cikakken turnkey PCB taro sabis masana'antu don samfur PCB taro da low girma, tsakiyar girma PCB taro.Abin da abokan cinikinmu ke buƙatar yi shi ne aika fayilolin ƙirar PCB da buƙatun zuwa gare mu, kuma za mu iya kula da sauran ayyukan.Muna da cikakkiyar ikon bayar da sabis na PCB na turnkey wanda ba za a iya doke su ba amma kiyaye jimlar farashi a cikin kasafin ku.

Idan kuna neman ƙwararrun masana'anta PCB na Turnkey, da fatan za a aika fayilolin BOM ɗinku da fayilolin PCB zuwa sales@pcbfuture.com.Duk fayilolinku sirri ne sosai.Za mu aiko muku da ingantaccen zance tare da lokacin jagora cikin sa'o'i 48.

Lokacin aikawa: Dec-13-2022