1. Hot iska solder matakin

Allon azurfa ana kiran allo mai daidaita allo mai zafi.Fesa Layer na tin a saman Layer na waje na da'irar tagulla yana haifar da walƙiya.Amma ba zai iya samar da amincin lamba na dogon lokaci kamar zinariya ba.Lokacin amfani da shi da yawa, yana da sauƙin oxidize da tsatsa, yana haifar da mummunan hulɗa.

Amfani:Ƙananan farashi, kyakkyawan aikin walda.

Rashin hasara:The surface flatness na zafi iska solder leveling jirgin ba shi da kyau, wanda bai dace da waldi fil tare da kananan rata da aka gyara da suke da ma kananan.Tin beads suna da sauƙin samarwa a cikiPCB aiki, wanda yake da sauƙi don haifar da gajeren kewayawa zuwa ƙananan abubuwan haɗin rata.Lokacin da aka yi amfani da shi a cikin tsarin SMT mai gefe biyu, yana da sauƙin fesa narke gwangwani, wanda ke haifar da ƙwanƙwasa ƙwanƙwasa ko ɗigon kwano mai siffar zobe, yana haifar da ƙarin rashin daidaituwa kuma yana shafar matsalolin walda.

2, Azurfa nutsewa

Tsarin azurfa na nutsewa yana da sauƙi da sauri.Azurfa nutsewa wani motsi ne na ƙaura, wanda shine kusan submicron tsantsa murfin azurfa (5 ~ 15 μ In, game da 0.1 ~ 0.4 μ m) Wani lokaci aiwatar da nutsewar azurfa kuma yana ƙunshe da wasu abubuwa na halitta, galibi don hana lalata azurfa da kawar da matsalar. na gudun hijira na azurfa.Ko da an fallasa ga zafi, zafi da ƙazanta, har yanzu yana iya samar da kyawawan kaddarorin lantarki da kuma kula da kyakkyawan walƙiya, amma zai rasa haske.

Amfani:A azurfa impregnated waldi surface yana da kyau weldability da coplanarity.A lokaci guda kuma, ba ta da cikas kamar OSP, amma ƙarfinsa bai kai zinariya ba idan aka yi amfani da shi azaman lamba.

Rashin hasara:Lokacin da aka fallasa zuwa yanayin rigar, azurfa za ta haifar da ƙaura na lantarki a ƙarƙashin aikin ƙarfin lantarki.Ƙara abubuwan da aka gyara zuwa azurfa na iya rage matsalar ƙaura ta lantarki.

3. Tin na nutsewa

Tin na nutsewa yana nufin wicking solder.A baya, PCB ya kasance mai saurin kamuwa da busassun gwangwani bayan aiwatar da tin na nutsewa.Tin barasa da ƙauran kwano yayin walda zai rage dogaro.Bayan haka, ana ƙara abubuwan da ke tattare da kwayoyin halitta zuwa maganin immersion na tin, don haka tsarin tin ɗin ya zama granular, wanda ya shawo kan matsalolin da suka gabata, kuma yana da kwanciyar hankali mai kyau da weldability.

Rashin hasara:Babban rauni na nutsewar kwano shine gajeriyar rayuwar sa.Musamman lokacin da aka adana shi a cikin yanayin zafi mai zafi da yanayin zafi mai zafi, mahadi tsakanin karafa na Cu/Sn za su ci gaba da girma har sai sun rasa abin sayarwa.Don haka, ba za a iya adana faranti masu ciki na dogon lokaci ba.

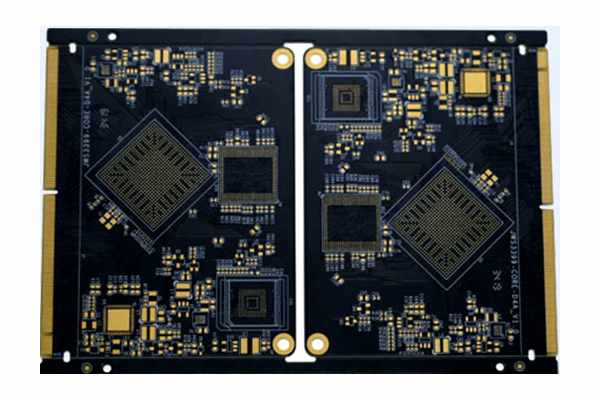

Muna da kwarin gwiwa wajen samar muku da mafi kyawun haɗin gwiwaturnkey PCB taro sabis, Inganci, farashi da lokacin isarwa a cikin odar taro na ƙaramin tsari na PCB da odar taro na PCB na Tsaki.

Idan kana neman madaidaicin masana'anta na PCB, da fatan za a aika fayilolin BOM ɗinku da fayilolin PCB zuwasales@pcbfuture.com.Duk fayilolinku sirri ne sosai.Za mu aiko muku da ingantaccen zance tare da lokacin jagora cikin sa'o'i 48.

Lokacin aikawa: Nuwamba-21-2022